Why Do Brand-new Headphones Get Moldy? Top Causes and Effective Prevention Tips for Manufacturers

![]() Date: Sep 23,2024

Date: Sep 23,2024

Over-ear headphones that developed mold despite using silica gel desiccants

In recent years, many headphone manufacturers didn’t use proper anti-mold protection, and their products ended up getting moldy during shipping and storage. This not only ruins the customer’s buying experience, but also hurts the brand’s reputation. Once mold grows, it damages both the appearance and the electronic components inside. That’s why factories and brands urgently need a simple and effective anti-mold solution.

1. Why New Headphones Mold Easily

1) Material Issues: Headphones are made from a mix of materials—plastic, metal, foam, fabric, and leather. The earmuffs often use PU, PVC, or real leather for comfort. Soft leather needs oils added in production, and these oils become food for mold. Sponges, foams, and fabrics inside are also very hygroscopic, easily absorbing moisture from the air.

2) Humid Production Environment: Headphone assembly involves many steps. If workshop humidity isn’t controlled, moisture gets trapped inside the complex structure of the headphones, creating a micro-humidity environment perfect for mold.

3) Packaging Materials: Many factories skip proper drying before packaging. Their packaging boxes often use breathable materials, making it easy for outside moisture to seep in. High-end headphone boxes also use a lot of glue, which itself feeds mold. Once the box molds, it spreads quickly to the headphones inside.

4) Poor Storage Conditions: If finished headphones are stored in damp, poorly ventilated warehouses, moisture will keep entering the packaging. Wooden pallets and cartons may also carry mold spores, making the problem worse.

2. How to Prevent Mold: Add Power Pak + Power Dryer

To keep headphones mold-free during global transport and storage, simply add iHeir Power Pak Anti-Mold Chips and iHeir Power Dryer H Series Desiccant inside the packaging. Usually, 1 chip + 1 pack per headphone is enough.

1) Drying Before Packaging: Make sure the headphones are fully dried before sealing. Use drying equipment to remove surface moisture.

2) Add Anti-Mold Power Pak & Desiccant: Place 1 Power Pak Anti-Mold Chip and 1 pack of iHeir Power Dryer H Series Desiccant (2–4g) inside each headphone box. Within 72 hours, they create a sterile, mold-proof environment. Power Pak anti-mold chips can continuously release antibacterial ingredients in a confined space, effectively inhibiting the growth of mold spores and keeping the inside of the headphones in a sterile state, thereby preventing mold growth and reproduction.

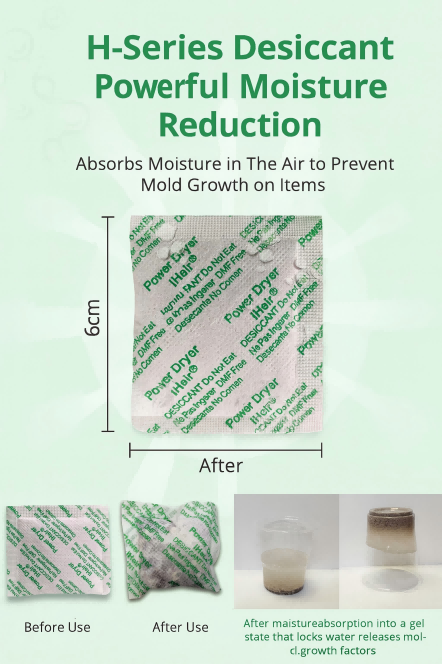

iHeir Power Dryer H Series Desiccant is made from natural minerals and uses natural plant fibers as the moisture-absorbing carrier. It is 100% naturally degradable and has a saturated moisture absorption capacity of up to 300% of its own weight (25°C, RH=100%), which is 20 times that of ordinary silica gel desiccants. Compared with other desiccants on the market, it not only features fast adsorption speed and high absorption capacity, but is also non-toxic, colorless, odorless, non-corrosive, and environmentally friendly. It can even be safely used in food packaging and is completely harmless to the human body.

3) Use Good Sealing Packaging: Choose packaging with strong sealing, like foil or vacuum bags, and pack together with anti-mold products. This locks out external moisture and extends protection.

4) Control the Storage Environment: After packaging, store headphones in a warehouse with stable temperature and humidity, and good ventilation. This avoids prolonged damp conditions that can trigger mold growth.

3. Conclusion

Mold on headphones not only affects product quality but also damages brand trust. By using Power Pak Anti-Mold Chips and iHeir Power Dryer H Series Desiccant, brands can ensure long-lasting mold protection, smooth global delivery, and products that reach shelves on time—earning customer trust and strong market reputation.

iHeir’s innovative anti-mold and antibacterial solutions have already been applied to over 3,000 products worldwide—covering shoes, bags, furniture, bamboo & wood products, packaging, electronics, and more. We help factories and brands achieve zero mold from production to delivery.